Float-Zone Neutron Transmutation Doped Silicon Wafer

OVERVIEW

——

Float-Zone Neutron Transmutation Doped Silicon Wafer. Oxygen-free, high purity and highest resistivity silicon can be gained by Float-zone FZ ( Zone-Floating) crystal growth, High resistivity FZ silicon crystal is often doped by Neutron Transmutation Doping (NTD) process, in which neutron irradiation on undoped float zone silicon to make silicon isotopes trapped with neutrons and then decay into the desired dopants to achieve the doping goal. Through adjusting the level of neutron radiation, the resistivity can be altered without introducing external dopants and therefore guaranteeing material purity. FZ NTD silicon wafers ( Float Zone Neutron Transmutation Doping Silicon) have premium technical properties of uniform doping concentration and uniform radial resistivity distribution, lowest impurity levels, and high minority carrier lifetime.

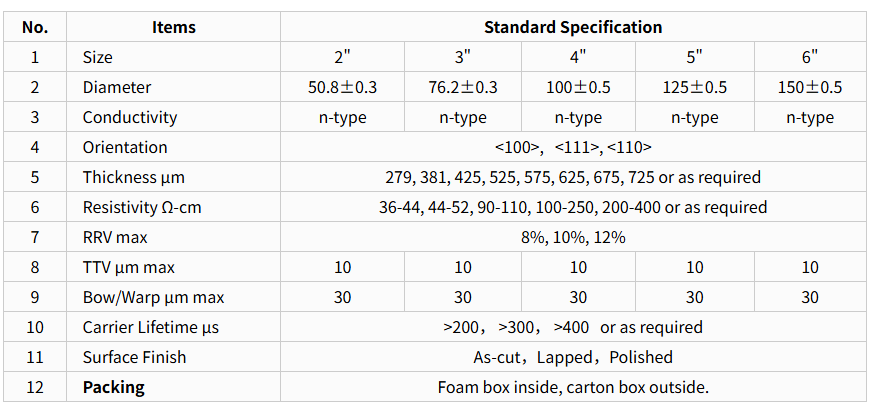

SPECIFICATIONS

——

Application

——

FZ-NTD Silicon Wafer is a paramount importance for applications in high power, detector technologies and in semiconductor devices that have to work in extreme conditions or where low resistivity variation across the wafer is required, such as gate-turn-off thyristor GTO, static induction thyristor SITH, giant transistor GTR, insulate-gate bipolar transistor IGBT, extra HV diode PIN. FZ NTD n-type silicon wafer is also as main functional material for various frequency converters, rectifiers, large-power control elements, new power electronic devices, photoelectronic devices, silicon rectifier SR, silicon control SCR, and optical components such as lenses and windows for terahertz applications.

Delivery

——

As a market leading supplier of NTD silicon for promising power applications, and following the growing demands for top quality level wafers, superior FZ NTD silicon wafer can be offered to our customers worldwide in various size ranging from 2″, 3″, 4″, 5″ and 6″ diameter (50mm, 75mm, 100mm, 125mm and 150mm) and wide range of resistivity 5 to 2000 ohm.cm in <1-1-1>, <1-1-0>, <1-0-0> orientations with as-cut, lapped, etched and polished surface finish in package of foam box or cassette, or as customized specification to the perfect solution.

FAQ

——

1. About Price:

All of our prices are competitive and negotiable. The price varies depending on the configuration and customization complexity of your device.

2. About Sample:

We can provide sample production services for you, but you may provide some fees.

3. About Payment:After the plan is confirmed, you need to pay us a deposit first, and the factory will start preparing the goods. After the

goods is ready and you pay the balance, we will ship it.

4. About Delivery:

After the goods manufacturing is completed, we will send you the acceptance video, and you can also come to the site to inspect the equipment.